Centrifugal pumps are one of the most commonly used types of pumps in industrial, commercial, and residential applications. They rely on the principle of centrifugal force to move fluids through a piping system. Among the various configurations available, vertical and horizontal centrifugal pumps are two primary categories that differ in design, application, and performance. This article delves into the key differences between vertical and horizontal centrifugal pump.

The specific differences between vertical centrifugal pumps and horizontal centrifugal pumps are as follows:

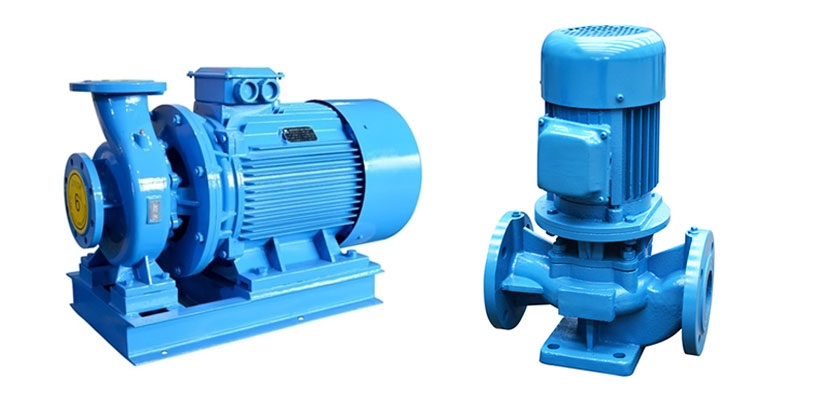

- Different appearance. The vertical pump is vertical, but the horizontal pump is horizontal.

- Different connection means. The vertical pump is superposed from bottom to top, and the horizontal pump is arranged on the basement in the vertical direction.

- Different covering space. The vertical pump covers a small area, but the horizontal pump covers a big area.

- The difficulty of maintenance is different. It is difficult to repair the vertical pump. In case of a maintenance, the impeller can be repaired after removing all upper parts. However, the horizontal pump is relatively easier.

- Different installation means. The vertical pump is in overall connection, and the installation is rather easy. However, the horizontal pump has to be conducted with the accuracy adjustment after installation.

- The pipeline arrangement has different requirements. The vertical pump can adopt vertical and horizontal installations of the pump. The inlet and outlet of the horizontal pump can be installed at 0/90/180°.

Application scenes:

The vertical centrifugal pump is divided into the vertical multi-stage centrifugal pump and the vertical single-stage centrifugal pump. Generally, a vertical multi-stage centrifugal pump is used for a small-flow high-lift centrifugal pump (commonly used in a building water supply system), and a single-stage centrifugal pump is generally used in conditions with rather balanced flow and lift (commonly used in closed circulation system).

The horizontal pump is used in conditions with big flow and small lift(commonly used in the building air-conditioner system). This centrifugal pump occupies a lot of space. The vertical single-stage centrifugal pump adopts the pipeline installation and can be directly installed on the pipeline, thus occupying no great space. However, the pump power generally does not exceed 75KW, otherwise, the pipeline may have a relatively large.

The horizontal centrifugal pump is required to install the basement. In normal conditions, it is the single-stage end suction port/double-suction pipeline downwards inlet and upwards outlet/horizontal inlet and outlet. The inlet pipe diameter is larger than the outlet pipe diameter. The power can be very high. Its efficiency is higher than the vertical pump, and it has a smaller shock on the pipeline. As to the big pump, it is usually recommended to adopt the horizontal type.

In short, the vertical centrifugal pump does not occupy a large space, but the power is not suggested to be too high. The horizontal type occupies a large space, but the efficiency is high, and the power can be very high.

Performance and operating conditions

Efficiency

Horizontal centrifugal pumps are generally more efficient for applications involving high flow rates and moderate pressures. Their straightforward design minimizes energy losses, making them ideal for general-purpose pumping tasks.

In contrast, vertical centrifugal water pumps excel in applications requiring the movement of fluids from deep or confined spaces. Although their efficiency might be slightly lower than horizontal pumps in some cases, their ability to reach deeper sources of fluid compensates for this difference.

Stability and Alignment

Horizontal pumps have better stability because they are mounted on a solid base. This design reduces vibrations and ensures smooth operation, which is crucial in applications involving heavy-duty workloads or high-speed operations.

Vertical pumps require precise alignment of the shaft and motor. Misalignment can lead to excessive wear, increased vibrations, and operational inefficiency.

Fluid Handling

Horizontal centrifugal water pumps are more versatile when handling a wide range of fluids, from water to viscous chemicals. They can easily integrate with piping systems for closed-loop operations.

Vertical pumps, however, are better suited for handling fluids in open tanks, reservoirs, or deep wells. Their design allows the impeller to be submerged directly in the fluid, making them ideal for applications like dewatering or wastewater management.

Installation and maintenance

Horizontal pumps are easier to install, provided there is ample floor space. However, their footprint can be a limitation in confined areas. And maintenance, the accessible layout of horizontal pumps simplifies maintenance tasks like seal replacement or impeller inspection.

Vertical pumps are more challenging to install due to their alignment requirements and the need for precise mounting. However, their compact footprint makes them advantageous in space-constrained environments. And maintenance, maintenance of vertical pumps can be more labor-intensive, especially for pumps installed in deep wells or with long columns.

Conclusion

Both vertical and horizontal centrifugal pumps play vital roles in fluid transportation systems, each excelling in specific applications. Horizontal pumps are known for their efficiency and ease of maintenance, while vertical pumps are celebrated for their compact design and ability to handle deep-sump or submerged operations. Understanding the structural differences, performance characteristics, and application scenarios is essential for selecting the right pump to meet operational needs effectively. Both types of centrifugal pumps are available in Inverter Online Store. By carefully evaluating the requirements of your application, you can make an informed decision, ensuring optimal performance and longevity of your pumping system.

cheers.