50 hp horizontal centrifugal pump with 65m3/h maximum flow, 128m maximum head, and 80mm diameter of inlet and outlet.

Features:

- The centrifugal pump has a horizontal structure. The diameter of the inlet and outlet are the same. If a protective cover is added, it can be used in the open air.

- It is easy to install and maintain. There is no need to dismantle the pipeline system, just lift off the conjunction flat nut of the vertical pump. Then, all the rotor parts can be taken out.

- A horizontal centrifugal pump can operate in series and parallel connection according to the requirements of flow and head.

- The installation angle of the pump outlet can be 0°, 90°, or 180° to meet different connection occasions.

Specifications:

| Model |

ATO-HCP-80-315 |

| Weight |

430kg |

| Size |

620*995*400mm |

| Power |

50 hp (37kW) |

| Phase |

3 phase |

| Input voltage * |

AC 220V, 230V, 240V, 380V, 400V, 415V, 440V, 460V, 480V |

| Input frequency * |

50Hz, 60Hz |

| Flow (min. flow to max. flow) |

35m3/h (154 gpm, American system) |

50m3/h (220 gpm, American system) |

65m3/h (286 gpm, American system) |

| Head (max. head to min. head) |

128m (420ft) |

125m (410ft) |

122m (400ft) |

| Efficiency |

43% |

54% |

57% |

| Inlet diameter |

80mm (3 inch) |

| Outlet diameter |

80mm (3 inch) |

| Installation angle of outlet |

0°, 90° and 180° |

| Nominal diameter of impeller |

315mm |

| Pump type |

Booster pump |

| Number of stages |

Single stage |

| Motor type |

Y/Y2 series motor |

| Motor speed |

2900rpm |

| Impeller material |

304/316 stainless steel |

| Seal material |

304 stainless steel, tungsten carbide, fluorine rubber |

| Inlet max. pressure |

1MPa (145 psi) |

| (NPSH)r |

3.0m |

| Usage |

Water or liquids compatible with pump component materials.

1. The volume of solid particles should be less than 0.1% in unit volume, and the granularity should be less than 0.2mm.

2. The temperature should be lower than 60℃. |

| Environment |

Temperature: <40℃, humidity: <95%, altitude<1000m |

| Warranty |

12 months |

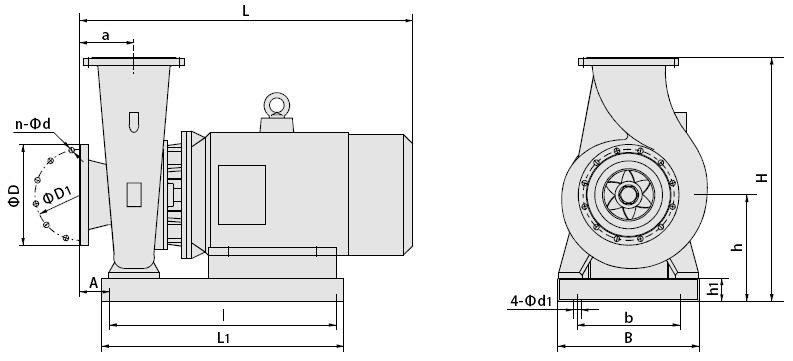

Horizontal centrifugal pump dimension (unit: mm):

| Boundary dimension |

Base dimension |

Flange dimension |

| h |

H |

L |

a |

A |

L1 |

B |

l |

b |

h1 |

4-Φd1 |

D |

D1 |

n-Φd |

| 325 |

620 |

995 |

125 |

85 |

700 |

400 |

650 |

300 |

100 |

4-Φ18 |

Φ200 |

Φ160 |

8-Φ18 |

Tips: Difference between the pipeline pump and centrifugal pump

Before distinguishing between the pipeline pump and the centrifugal pump, it is necessary to explain what a centrifugal pump is. A centrifugal pump is a kind of pump that conveys the liquid relying on the centrifugal force generated by the impeller rotation. The high-speed rotating impeller blade drives the water rotation, throwing the water out to achieve the purpose of transmission. Centrifugal pumps have vertical, horizontal, single-stage, multi-stage, single-suction, double-suction, self-suction, pipeline-type, and several other forms. Therefore, centrifugal pump is a large pump species, which are widely used in many industrial and civil fields. Its market share is at least 90%. The centrifugal pumps mentioned above include vertical, horizontal, single-stage, multi-stage, single-suction, double-suction, self-suction, pipe-type, and many other forms. The pipeline type here refers to the pipeline pump we often say. It is not difficult to see that the pipeline pump is a special centrifugal pump. The industry defines the pipeline pump as follows: a pipeline pump is a centrifugal pump with the water inlet and outlet levels being on the same line. That is, it has the shape of a pipe, and it can be directly installed on the pipeline to pressurize the liquid. The structure of the pump body has no great difference. The pipeline pump is mostly a single-stage pump, but some pipe pressurizing pumps with special requirements use the multistage pump. In most conditions, they are ordinary pipeline pumps. The pipe pressurizing pump is a gas station in the pipeline. When the pipeline is laid very long, the flow of the fluid in the pipeline is not enough to overcome the resistance of the pipeline, a pressurizing pump must be increased to increase the pressure of the fluid in the pipeline to transport to a further distance. Summary: The Centrifugal pump is the original model of the pipeline pump, and the pipeline pump is included in the category of centrifugal pumps. [The pipeline pump is a centrifugal pump with a special structure. It has the advantages of easy installation and maintenance (requiring no disassembly of the pipeline in maintaining the impeller, pump body, and bearing), a wide range of performance, technical maturity, and so on. Therefore, it is recommended to prioritize the pipeline pump where the performance range allows.