75 hp horizontal centrifugal pump with 65m3/h maximum flow, 146m maximum head, and 80mm diameter of inlet and outlet.

Features:

- The centrifugal pump has a horizontal structure. The diameter of the inlet and outlet are the same. If a protective cover is added, it can be used in the open air.

- It is easy to install and maintain. There is no need to dismantle the pipeline system, just lift off the conjunction flat nut of the vertical pump. Then, all the rotor parts can be taken out.

- A horizontal centrifugal pump can operate in series and parallel connection according to the requirements of flow and head.

- The installation angle of the pump outlet can be 0°, 90°, and 180° to meet different connection occasions.

Specifications:

| Model |

ATO-HCP-80-350 |

| Weight |

630kg |

| Size |

650*1250*500mm |

| Power |

75 hp (55kW) |

| Phase |

3 phase |

| Input voltage * |

AC 220V, 230V, 240V, 380V, 400V, 415V, 440V, 460V, 480V |

| Input frequency * |

50Hz, 60Hz |

| Flow (min. flow to max. flow) |

35m3/h (154 gpm, American system) |

50m3/h (220 gpm, American system) |

65m3/h (286 gpm, American system) |

| Head (max. head to min. head) |

146m (479ft) |

150m (492ft) |

142m (466ft) |

| Efficiency |

55% |

66% |

67% |

| Inlet diameter |

80mm (3 inch) |

| Outlet diameter |

80mm (3 inch) |

| Installation angle of outlet |

0°, 90° and 180° |

| Nominal diameter of impeller |

350mm |

| Pump type |

Booster pump |

| Number of stages |

Single stage |

| Motor type |

Y/Y2 series motor |

| Motor speed |

2900rpm |

| Impeller material |

304/316 stainless steel |

| Seal material |

304 stainless steel, tungsten carbide, fluorine rubber |

| Inlet max. pressure |

1MPa (145 psi) |

| (NPSH)r |

3.0m |

| Usage |

Water or liquids compatible with pump component materials.

1. The volume of solid particles should be less than 0.1% in unit volume, and the granularity should be less than 0.2mm.

2. The temperature should be lower than 60℃. |

| Environment |

Temperature: <40℃, humidity: <95%, altitude<1000m |

| Warranty |

12 months |

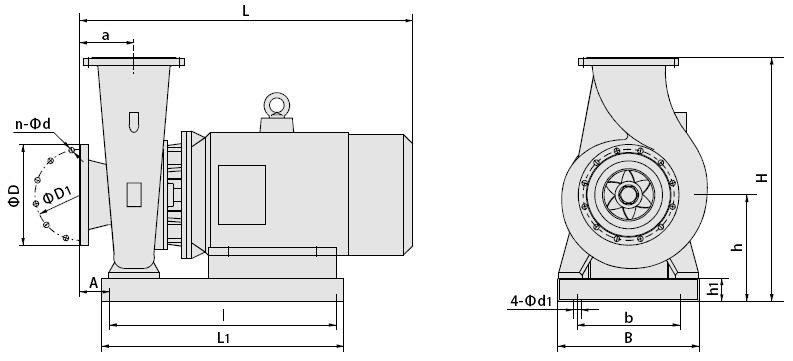

Horizontal centrifugal pump dimension (unit: mm):

| Boundary dimension |

Base dimension |

Flange dimension |

| h |

H |

L |

a |

A |

L1 |

B |

l |

b |

h1 |

4-Φd1 |

D |

D1 |

n-Φd |

| 325 |

650 |

1250 |

130 |

90 |

830 |

500 |

750 |

300 |

100 |

4-Φ22 |

Φ200 |

Φ160 |

8-Φ18 |

Tips: What are the accessories of the centrifugal pump?

In installing the pipe centrifugal pump, some accessories are required, such as check valves, globe valves, pressure gauges, control cabinets, or the like. The check valve, also known as the bottom valve, is a device that prevents backflow. A simple example is given here: when a pipeline centrifugal pump is installed, if its inlet is at a high point, the outlet of the pump must be fitted with an accessory. These accessories is the pressure gauge and the check valve. The function of the check valve is to prevent the water in the pipe from having backflow when the pump stops running. If the check valve is not qualified (that is, the quality is not good), the backflow into the pump will cause the pump to rupture. This condition is quite common. When the pipeline centrifugal pump is used as a self-suction pump, a check valve is in more urgent need. In such a condition, we generally call it the bottom valve. At this time, the water inlet of the pump is below, that is, the centrifugal pump is required to suck the water up. We all know that the pipe pump has no suction stroke, but we can still use it as a self-suction pump as long as we add a bottom valve to it. However, this will reduce the head of the pump. If the bottom valve is not qualified, the water inside the inlet pipe will completely leak into the pool. When the pump is started, the impeller will have dry revolving when there is no water in the pipeline. This will damage the pump seal and even destroy the impeller or burn the motor.